環保設備 行噴脈沖袋收塵器

結構特點

行噴脈沖袋收塵器,用(yòng)于氣體(tǐ)中固體(tǐ)顆粒的去除和收集,适用(yòng)于水泥熟料冷卻機、窯尾及生料磨、烘幹機等大氣量高溫氣體(tǐ)的收塵;可(kě)用(yòng)于各種水泥、礦渣、煤粉磨系統成品料粉收集及除塵工藝;同時适用(yòng) 于冶金、電(diàn)力、化工、機械和民(mín)用(yòng)鍋爐等廢氣除塵。最小(xiǎo)排放濃度可(kě)達到2mg/Nm3。

●獨特室内換袋(Walk in)結構,保證設備漏風率真正低于 2.5%。減少了設備鏽蝕,也降低了收塵器後風機能(néng)耗。

The specially-designed walk-in plenum structure facilitates the replacement of filter bags from inside the

filter housing, thus ensuring air leakage to be under 2.5%, to prevent corrosion by rust and to lower energy

consumption of the fans due to minimum of false air;

●基于 CFD 技(jì )術的氣流分(fēn)布、清灰模拟和設備強度整機結構優化,确保更合理(lǐ)的結構。

Optimum structure ensured by CFD-based gas distribution, de-dusting simulation and the overall

optimization of the equipment;

●關鍵裝(zhuāng)置噴吹管和噴吹單元獲得多(duō)項國(guó)家發明專利和實用(yòng)新(xīn)型專利,高效清灰,并保證了脈沖閥和濾袋的使

用(yòng)壽命更長(cháng)。

Key devices, the purge tube and the purge unit, are patented with several national invention and utility

model patents. De-dusting efficiency and extended service life of the pulse valve and the filter bag can thus

be guaranteed;

●标準闆塊結構設計,方便現場安(ān)裝(zhuāng),并利于結構密封施焊。

Modular design, easy for erection at site and for applying sealing welds;

●完美的清灰控制系統, PLC 控制,可(kě)方便實現清灰程序、間隔、強度可(kě)調,同時設置運行參數監控顯示。

The well-designed de-dusting control system is PLC-based, which allows to conveniently adjust the mode,

interval and intensity of the de-dusting program and to display all relevant operational parameters;

●采用(yòng)智能(néng)運行監測系統,确保生産工藝設備的可(kě)靠運行。

A smart monitoring system is used, which ensures reliable operation of this important process equipment.

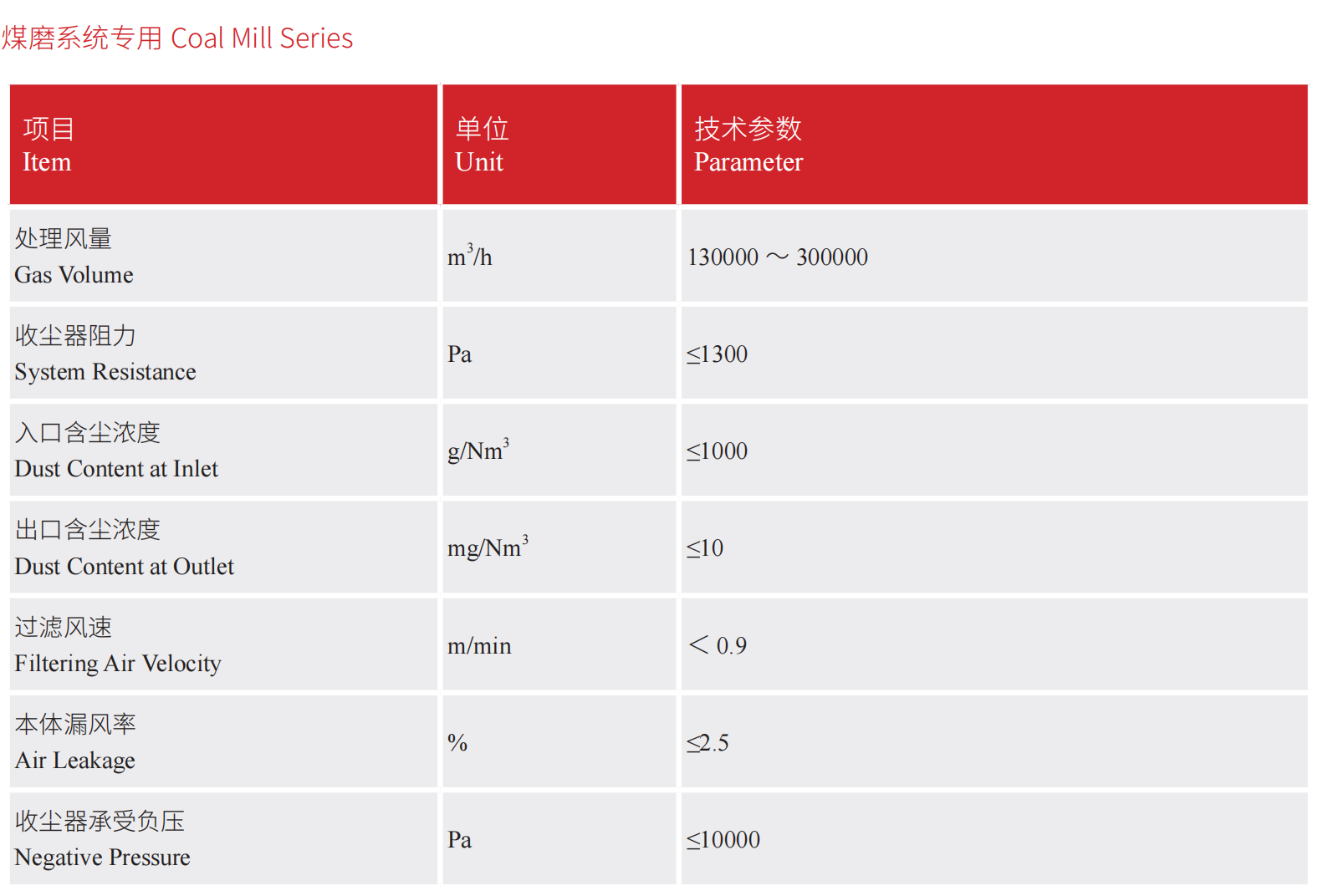

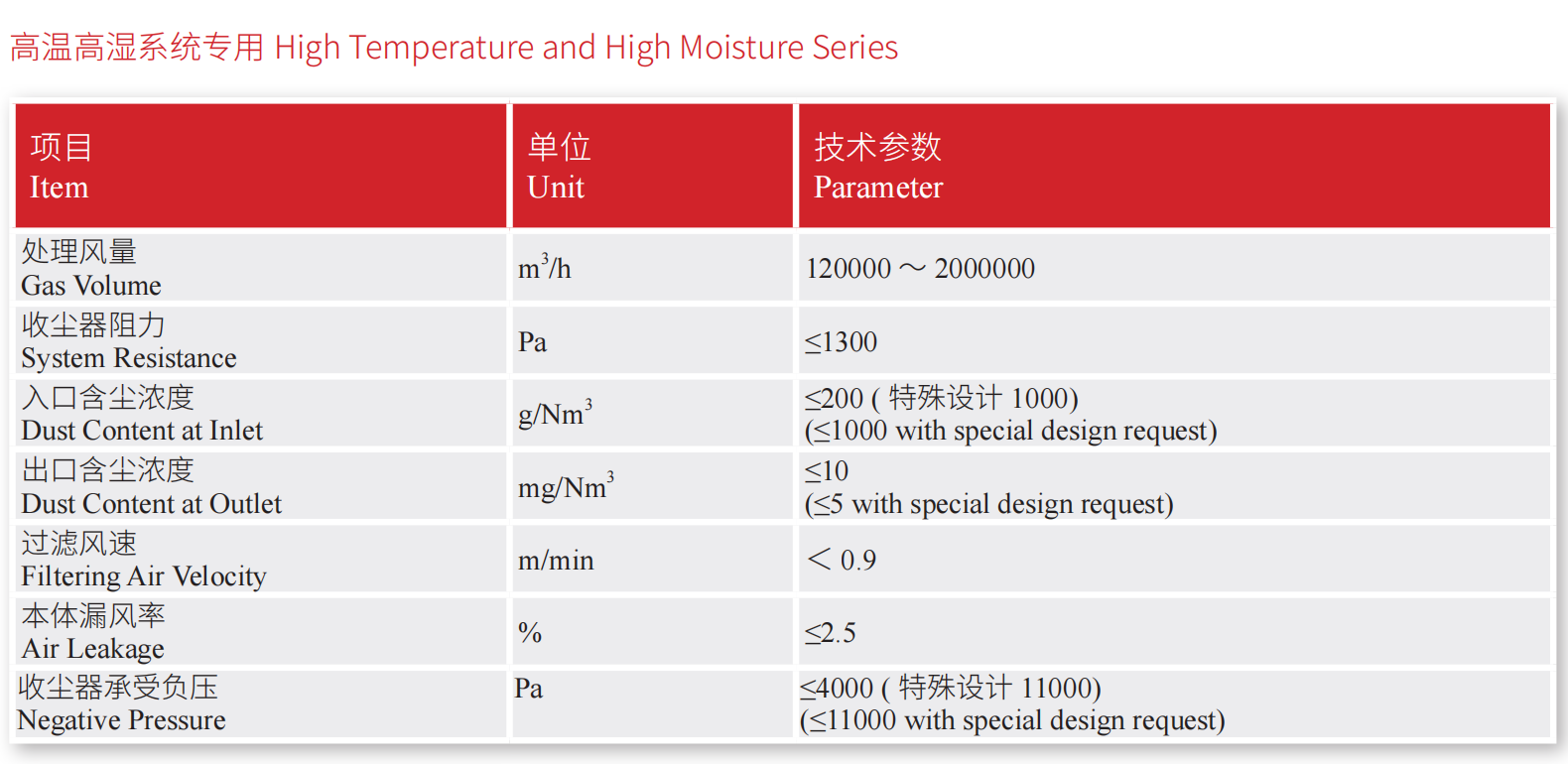

技(jì )術參數